Manufacturing Processes

DGS keeps all core processes within its own in-house production facilities to ensure process stability and unified quality. Many of our manufacturing steps are automated and real-time monitored using state-of-the-art technology. With our traceability solution in all our locations in the world, we are able to track each part by storing individual process information and quality results in a central database system that links the relevant information to the subsequent process steps.

Services

-

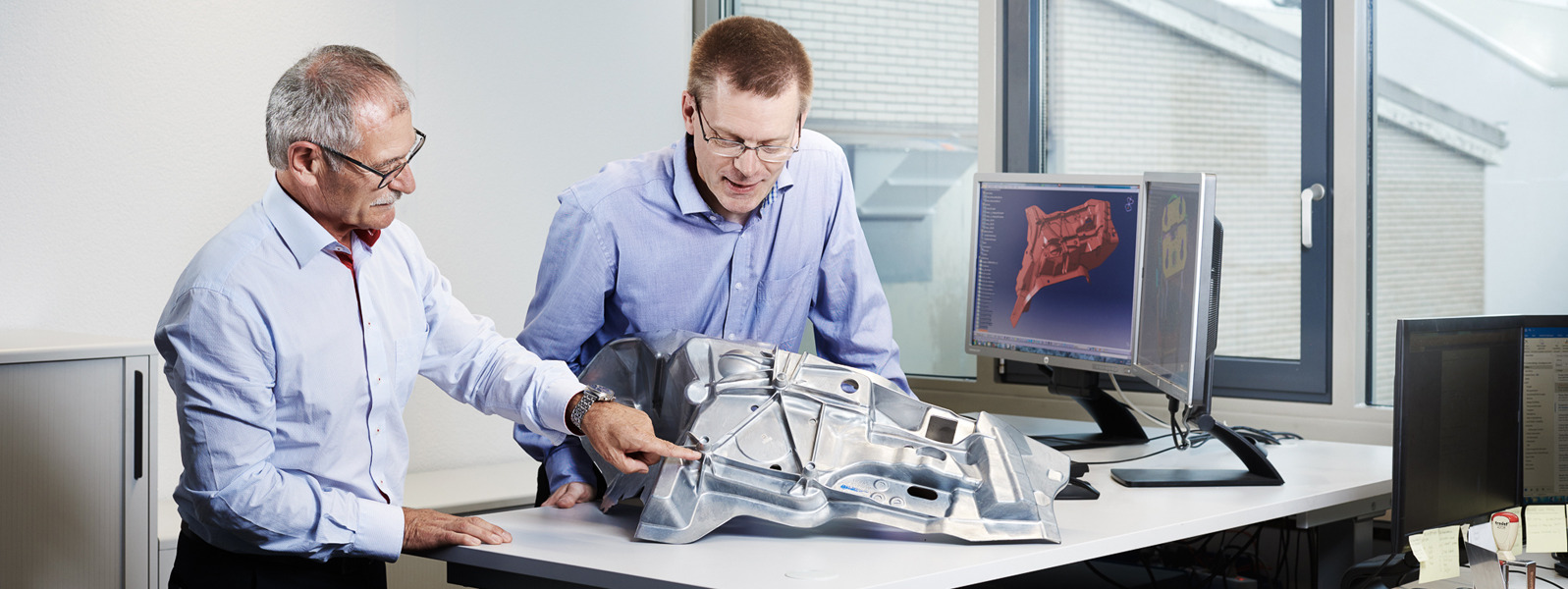

DGS is the ideal partner wherever light metal components with the highest requirements for dimensional accuracy, surface finish and special mechanical properties are required.

- Comprehensive knowledge and a versatile machine park allow us to process aluminum and magnesium alloys according to common die casting processes, even under vacuum.

- All our manufacturing plants pursue the same high standards which are facilitated by mutual exchange of know-how and cross-border training programs of our employees.

Benefits

- All processes in-house

- Best possible machine concept

- Maximum concatenation

- High degree of automation

- High productivity

- Short delivery and response times

- No buffers

A satisfied customer will always return to us, be it with new development tasks or with sophisticated and innovative products. We want him to become «best in class».

Claus ScheppHead of Sales

DGS Druckguss Systeme AG