History

The foundry was established in 1925 as an "experimental laboratory" for the die casting department of Bühler AG in Uzwil. In 1950, it was moved to its current location in St. Gallen-Winkeln. In 1999, the company was taken over by the Von Roll Group and later on in 2003 acquired by the management and renowned entrepreneurs in the Eastern Switzerland region. Since then, we are known under the name of DGS Druckguss Systeme AG.

History chronological

2023 | Start of production in DGS Frýdlant

Launch of production in DGS Frýdlant

Our new plant in Frýdlant started the first production on April 28th, 2022 (exactly 1 year after the groundbreaking). In the meantime, the first customers audits have been successfully passed and from November 2022 series deliveries of aggregate and battery components for BEV vehicles from Mercedes and BMW have begun. Apart from all the necessary post-process equipments such as heat treatment, machining, assembly, etc. we have installed 2 die-casting cells up to 2700 tons of closing force.

2021 I Serial production in DGS Rizhao

Serial production in DGS Rizhao

Our new plant in Rizhao has successfully passed the audits of the first customers and started with serial deliveries of structural parts from January 2021. Besides all necessary post-processing equipment, such as heat-treatment, machining, assembly etc., we have installed 4 big die casting cells up to 4400 tons so far.

2021 I Groundbreaking for a new foundry in Frýdlant / Czech Republic

Groundbreaking for a new foundry in Frýdlant / Czech Republic

The groundbreaking ceremony for our second plant in the Czech Republic in Frýdlant was on the 28th of April 2021. This is an important milestone for the further expansion and development of the whole DGS Group. The first section of this plant will be finished in April 2022.

2017 I Planning of plant expansion in Liberec

Start of plant expansion in Liberec with SOP 2019

DGS significantly expands the production site in Liberec and also enlarges the degree of added-value in the process chain.

2015 I Expansion of site in Liberec for structural casting production

Implementation of production lines for body parts

In 2015, DGS in Liberec was extended by an additional hall for structural casting including post-processes. That was the beginning of a comprehensive technology transfer from Switzerland to the Czech Republic.

2013 I Construction of new "Greenfield location" Nansha, China with structural casting production

DGS is expanding its production capacities in China with a new foundry and additional die casting machines, including various value-added process steps.

The Nansha plant was inaugurated on 22 November 2013 in an official ceremony with representatives of the automotive industry, partner companies, suppliers and local authorities.

2012 I Change of leadership

Handover to new CEO

After 25 years as CEO of DGS Druckgusssysteme AG, Alfred Lichtensteiger hands over the operational management to the German national Andreas Müller.

2007 I Establishment of site in China, Nansha

Entry into the Chinese market

With the establishment of the site in Nansha, Guangzhou, South China, DGS emphasizes its strong commitment to the joint globalization steps with its key customers for the Asian market.

2005 I Expansion in St. Gallen with new "Hall East" for large die casting cells / entry into structural casting

In 2005, the new "Hall East" was acquired and expanded to a foundry for large die casting cells

With the joint strengthener application for Audi, DGS entered structural die casting business with the relevant secondary processes.

2003 I Becoming independent by the management and regional entrepreneurs / development of handbrake systems for VW

In the phase of restructuring the Von Roll Group has sold the two plants DGS Switzerland and DGS Czech Republic in 2003

These were taken over by two leading industrial holdings which merged the two plants to the newly formed DGS Druckguss Systeme AG. In the same year, the magnesium handbrake system for VW (platform PQ35) was developed and successfully launched in the market.

2000 I Disposal of injection molding

The composite business was sold to the company BIRO Edwin Bischof AG

In connection with the sale, the existing customer portfolio and injection molding machinery were moved to Romanshorn.

1999 I Takeover by Von Roll Group / acquisition of the business in Liberec

In 1999, the Swiss industrial group Von Roll took over the die casting and injection molding business from Bühler Druckguss AG in St. Gallen, which was established in the 1950s and became the new company Von Roll Druckguss AG.

In 2000, Von Roll acquired the plant in Liberec in the Czech Republic, from Frantisek Svobodnik - Alupress, which was founded in 1991. The operations were fully integrated into the newly established Von Roll Alupress s.r.o.

1996 I First large-scale order in the automotive industry

The path towards globalization and becoming an automotive supplier

Production of VW gearshift housings as the first large series product for the automotive industry.

1995 I Entry into magnesium

One step ahead...

In order to cope with prospective weight reduction demands by customers, Bühler Druckguss AG initiates first attempts to cast magnesium alloys for the bearing bracket used in power tool applications of Scintilla / Bosch.

1985 I Mr. Alfred A. Lichtensteiger takes over the leadership from Mr. Oskar Ronner

Change of leadership

Mr. Alfred A. Lichtensteiger takes over the operational leadership of the company and starts with the build-up of a quality management system according to the standard SN 029100B as the first foundry in Switzerland. Numerous new customers in neighbouring Europe could be acquired and the business continued to expand.

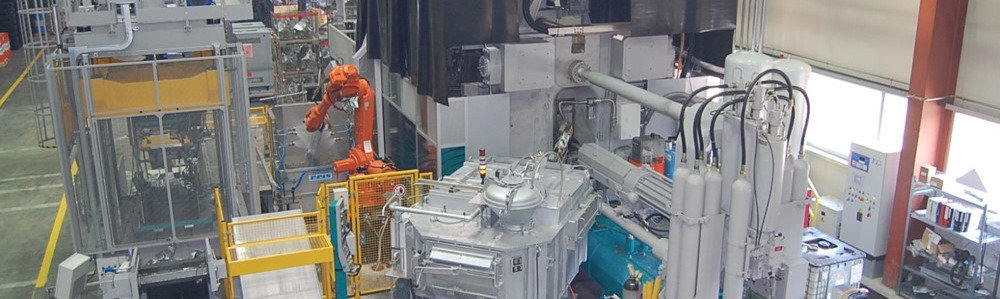

1973 I First steps towards automation

1973 marked the beginning of major efforts to automate various process steps

In 1975, short-time work was introduced and staff numbers were reduced from 340 to 220 employees in St. Gallen. In the same year, Gebr. Bühler AG won Knorr Bremse KG as the first foreign customer.

1965 I Major expansion with new office building, toolshop and warehouse

Major expansion with new office building, toolshop and warehouse

Main business with die casting parts was for BERNINA sewing machines. Further connecting manufacturing facilities were located in Urnäsch, Mogelsberg, Nesslau and Neu St. Johann facilitating the main production in St. Gallen.

1959 I Further expansion including the set-up of a plastic injection molding facility

Expansion of production

Further expansion up to 1959 including the construction of a plastic injection molding plant with 8 Bühler injection molding machines.

1950 I Establishment of foundry by Gebr. Bühler AG Uzwil in St. Gallen-Winkeln

The company was acquired by Gebr. Bühler AG Uzwil from Scandola AG and extented to a foundry. In 1992, the company was renamed Bühler Druckguss AG with first contacts established to Alupress in the Czech Republic.

Scandola AG manufactured machines for the production of preserving jars. Apart from high-pressure die castings, Gebr. Bühler AG, Druckguss and Spritzgusswerk AG also manufactured the "Kobold" vacuum cleaner.

1932 I

Entry into the production of zinc castings

Enhancement of the product portfolio

With the letter opener for the company Hasler the first steps in the processing of zinc alloys took place.

1925 I The beginning as "experimental laboratory"

The foundry was established in 1925 as an "experimental laboratory" of the die casting department of Bühler AG in Uzwil

The company emerged from Bühler AG in Uzwil which was founded in 1860. In the 1920s, they began to use die casting technology for the production of aluminum parts for the construction of their own mill processing equipment. Since the die casting machines purchased in the USA did not meet Bühler's requirements, the company began to develop and build its own die casting machines. The first metal die casting machine was put into operation in 1927.